编者按I:最近一期(2019年7月)TAPPI Journal杂志刊登了一篇柑橘皮纤维水性胶体用作纸张涂料流变助剂的论文,引起我们的兴趣。现将其部分内容进行编译和点评,以飨读者。

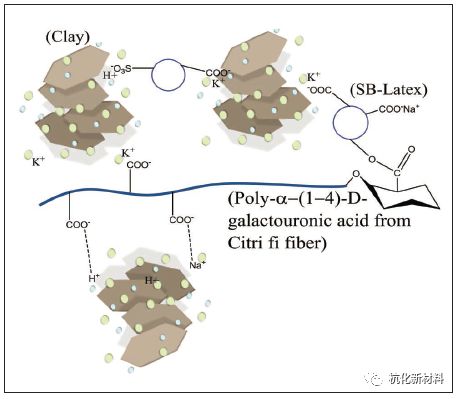

摘要:纸张涂料体系的流变性能和脱水性能不仅影响涂布机的运行性能,还影响最终涂布纸的质量。本文对柑橘皮纤维水性胶体(两种)用作纸张涂料流变改性剂进行了介绍。将该天然水性胶体与羧甲基纤维素(CMC)作用于一个具有代表性的涂料配方,对它们的应用效果进行了比较。结果表明:与不使用流变改性剂的涂料相比,使用柑橘皮纤维使涂料的保水性增加了56%,且保水性高于使用CMC的涂料。研究发现涂料的表观粘度(布鲁克菲尔德粘度)随柑橘皮纤维用量的增加而增加。柑橘皮纤维能使涂料的保水性达到与使用CMC的相似或更高,而粘度没有变化或略有增加。采用迈尔(Mayer)棒涂法将涂料涂布于挂面板纸,并测定纸张的通用物性以评估柑橘皮纤维流变剂对涂层功能的影响。结果表明:使用柑橘皮纤维流变剂可以改善涂布纸的亮度、孔隙率、平滑度、表面结合强度、油墨吸收性等性能。

ABSTRACT: The rheological and dewatering behavior of an aqueous pigmented coating system not only affects the machine runnability but also affects the product quality. The current study describes the use of natural hydrocolloids derived from citrus peel fibers as a rheology modifier in paper coating applications. The results were compared with carboxymethyl cellulose (CMC) in a typical paper coating system. Water retention of the coating formulation was increased by 56% with citrus peel fibers compared to a default coating, and it also was higher than a CMC containing coating. The Brookfield viscosity of paper coatings was found to increase with citrus peel fibers. Compared to CMC, different citrus peel fibers containing coating recipes were able to achieve similar or higher water retention values, with no change or a slight increase in viscosity. Coatings were applied on linerboard using the Mayer rod-coating method, and all basic properties of paper were measured to assess the impact of citrus peel fiber on the functional value of the coatings. Paper properties were improved with coated paper containing citrus peel fibers, including brightness, porosity, smoothness, surface bonding strength, and ink absorption.

应用:柑橘皮纤维含有大量的果胶,能赋予纸涂料体系优异的流变控制效果。该技术可为产业引入一种新型的绿色化学助剂,同时促进废弃柑橘皮副产物的再循环利用。

Application: Due to the high content of pectin present in citrus peel fibers, they have shown excellent control of rheology in a paper coating system. The industry impacts for this technology include introduction of a green chemical and upcycling of a waste byproduct from discarded citrus peel.

编者按II:

1. 该研究采用的两款柑橘皮纤维由美国Fiberstar Inc.公司提供,型号分别为Citri-Fi 125F和Citri-Fi 125 M40。除上述内容外,原作者还强调:与CMC需预先溶解好再使用相比,125F和125 M40可以直接以粉末的形式加到涂料配方中,因此更为便利、节能。

2. 该研究考察涂料特性时,采用的流变仪为Hi-shear Hercules Viscometer(Kaltec Scientific, USA),涂料保水性的测定遵照TAPPI Standard Test Method T701进行,前者的缺陷是“高剪切速率”还不够高,后者的缺陷在于获得的是静态保水性数据,建议业内更多地关注超高剪切流变仪和动态保水度测定仪的使用。

3. 关于流变改良剂,除了本文重点讨论的柑橘皮纤维、CMC以及在绪论中提及的碱溶胀型乳液(alkali-swellable emulsion)之外,现阶段合成缔合型增稠剂(associative thickener)在工厂中的应用也日趋普遍(国家造纸化学品工程技术中心联合韩国合作单位推出的NRC5001和NRC-5001N即为该类产品)。与溶胀增稠型流变剂主要与涂料中的自由水进行结合不同,缔合型增稠流变剂在与水作用的同时,还能与颜料粒子和胶乳粒子也产生作用,因而能提供更合理的保水性和流变性能,涂料为高固含量或处于高剪切速率条件下其效果尤为明显。对缔合型增稠流变剂,我们将另行撰文进行更详细的介绍。

原文出处:

Tyagi, P., Joyce, M., Agate, S., et. al.,TAPPI J. 18 (7): 443 (2019).

DOI: https://doi.org/10.32964/TJ18.7.443